Different types of industrial pressure gauges

©

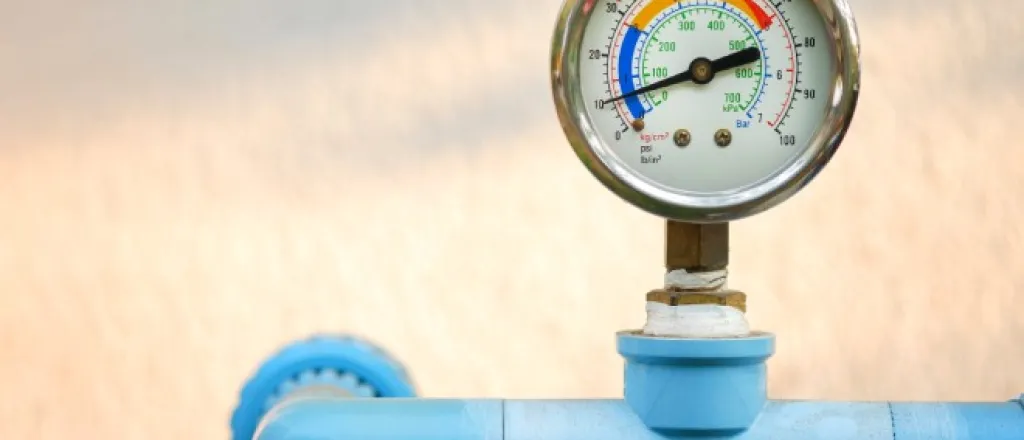

Though small and often overlooked, pressure gauges are essential instruments across various industries. They provide accurate readings to ensure system safety and efficiency. Here, we explore a few different types of industrial pressure gauges, explaining their functions and applications.

Bourdon tube pressure gauge

The Bourdon tube pressure gauge is a classic choice. It features a coiled tube that reacts to pressure changes. This mechanical deformation translates into a reading on the gauge.

Known for its durability and accuracy, the Bourdon tube pressure gauge serves well in applications requiring robust performance, such as petrochemical and gas industries.

Diaphragm pressure gauge

Diaphragm pressure gauges utilize a thin membrane to measure pressure. The pressure applied deforms this membrane, and the movement gets converted into a readable measurement.

These gauges excel in measuring low pressure and are particularly useful when dealing with gaseous media or corrosive substances.

Digital pressure gauge

Digital pressure gauges combine precision with ease of use. They display pressure readings electronically, often providing additional features, like data logging and alarms.

Digital pressure gauges are adaptable, serving in environments ranging from laboratories to manufacturing plants. Their straightforward digital interface allows users to interpret readings without the guesswork associated with analog dials.

Capsule pressure gauge

In low-pressure applications, capsule pressure gauges shine. These gauges use two identical capsule chambers to measure minute pressure differentials.

Highly sensitive, capsule pressure gauges are ideal for monitoring pressure in atmospheric or ventilation systems. They provide stable readings even under fluctuating environmental conditions, making them reliable and precise.

Differential pressure gauge

Differential pressure gauges offer vital information in industries that require monitoring the pressure difference between two points. These gauges find significant usage in filtration systems, refrigeration, and level measurement within tanks.

Liquid-filled pressure gauge

Liquid-filled pressure gauges contain a liquid, typically glycerin or silicone, that acts as a dampening medium. The liquid minimizes needle oscillations caused by system vibrations or pulsations, offering sustained accuracy. There are many benefits of choosing liquid-filled gauges for industries employing heavy machinery because of their resilience in challenging environments.

Understanding the different types of industrial pressure gauges empowers professionals to select the right tool for their specific needs. These instruments each serve a unique purpose, contributing to precise and efficient system operations across industrial sectors.