How environmental factors affect CMM accuracy

©

When you work with coordinate measuring machines (CMM), precision is the name of the game. These machines measure components with unmatched accuracy. However, even the most advanced CMM is only as good as the environment it operates in. Understanding how environmental factors affect CMM accuracy is vital for professionals aiming to maintain reliable and error-free measurements.

The effects of temperature

Temperature fluctuations can be a silent disruptor of measurement accuracy. CMM components and the workpiece being measured expand or contract based on the surrounding temperature. Even a slight change of a few degrees can result in measurement errors. Maintain a stable room temperature, ideally around 68°F, and give your equipment and components enough time to acclimate for optimal results.

The role of humidity

High humidity levels can introduce unnecessary moisture into the atmosphere, potentially forming condensation on equipment or workpieces. Too much humidity may affect sensitive components and even corrode metal parts, compromising accuracy. Keep the humidity level controlled with a dehumidifier if necessary. Aim for a range of 40–60 percent relative humidity to maintain a neutral and consistent environment.

The impact of vibration

CMMs and vibration do not mix well. Whether from nearby machinery, foot traffic, or operator movement, vibrations can distort your readings. Vibration isolators or dedicated vibration-damping platforms can significantly reduce this risk, ensuring that your CMM delivers consistent and credible results.

Air quality challenges

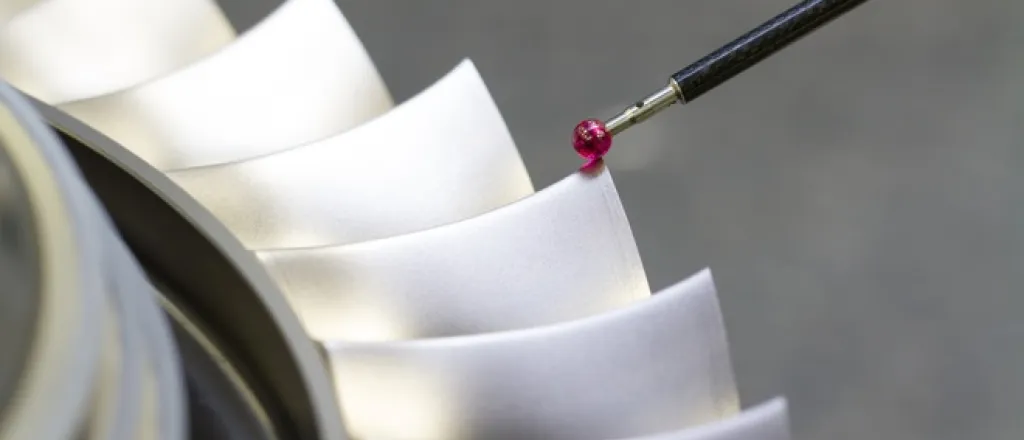

Believe it or not, even the air you breathe can mess with your CMM’s functionality. Dust and particulates can settle on the straight measuring stylus, leading to erroneous measurements. Ensure your CMM room remains clean and dust-free by investing in high-quality air filtration systems and enforcing strict housekeeping practices.

Lighting conditions and optics

Lighting conditions may seem trivial, but they matter more than you might think, especially if your CMM uses optical sensors. Poor lighting can interfere with the machine's vision systems, making it harder to achieve reliable results. Bright, glare-free LED lighting in the CMM area ensures that optical sensors have the clarity they need to function effectively.

Understanding how environmental factors affect CMM accuracy is essential for minimizing errors and improving performance. Controlling the above variables as much as you can will help you create a stable environment that allows your CMM to deliver the precision it’s designed for. Evaluate your CMM workspace today and start implementing changes to keep your measurements consistent and dependable.