The pros and cons of manual and automated crimping

©

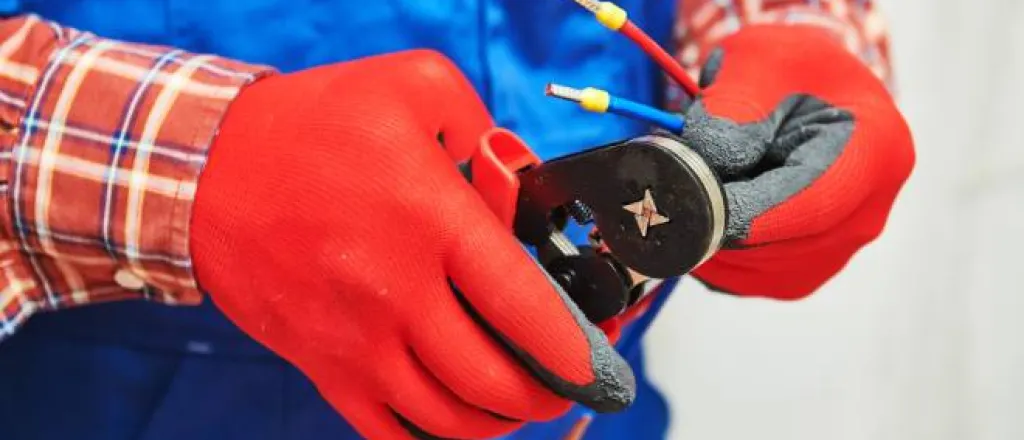

Crimping is essential for creating secure connections between wires and connectors. The two methods for crimping, manual and automated, offer pros and cons. We’ll break down the advantages and disadvantages of each method.

Manual crimping

The pros

Manual crimping involves using hand tools to compress a connector onto a wire, creating a secure bond. One of the primary advantages of manual crimping is its simplicity.

The necessary tools—namely crimpers and wire strippers—are generally inexpensive and easy to use. Manual crimping is ideal for small-scale projects or tasks requiring flexibility. Technicians appreciate the control they have over each crimp, allowing for adjustments based on the requirements of the job.

The cons

Manual crimping is not without its drawbacks. The process can be time-consuming, particularly for large projects that require numerous crimps. Additionally, the reliance on human skill creates a higher potential for error. Inconsistent pressure application can result in weak connections, which may compromise the integrity of the electrical system.

Automated crimping

The pros

Automated crimping machines offer a range of benefits that make them attractive to many electrical professionals. One of the most significant advantages is precision.

Automated machines apply consistent pressure, creating identical crimps. This level of accuracy is particularly beneficial for large projects necessitating repeatability. Automated crimping also reduces the time required to complete a project, as machines can perform multiple crimps in a fraction of the time it would take manually.

The cons

Despite these benefits, automated crimping machines present challenges. The initial cost of purchasing an automated crimping machine can be prohibitive, particularly for smaller operations.

Additionally, these machines require specialized training to operate. Automated crimpers require regular maintenance to ensure quality and longevity, which can delay project timelines.

Choosing between manual and automated

Now that we’ve discussed the pros and cons of automated and manual crimping, we can delve into the factors that help electricians choose between the two methods. The type of work or project is one of the most important considerations. Manual crimping suffices for small-scale projects that require flexibility. On the other hand, automated crimping machines are the better choice for large-scale projects.

Budget is another crucial factor. Manual crimping tools are relatively inexpensive, and the initial investment in automated crimping machines can be significant. Weigh the long-term benefits of increased efficiency and precision against the upfront costs.

Conclusion

Both manual and automated crimping methods have advantages and disadvantages. Understanding the needs of your project can help you choose between manual and automated crimping. Carefully evaluate both methods and the requirements of your project to choose the ideal crimping style.