Brief history of filter presses: how they’ve evolved

©

Filter presses may not be the talk of the town, but they’ve played a crucial role in industrial processes since the 18th century. You might be curious about how these machines have evolved and why they’re still relevant today. Well, you’re in the right place!

This article will take you through the fascinating history of filter presses, their evolution over the years, and their impact on various industries. By the end, you’ll have a solid understanding of their significance and future potential.

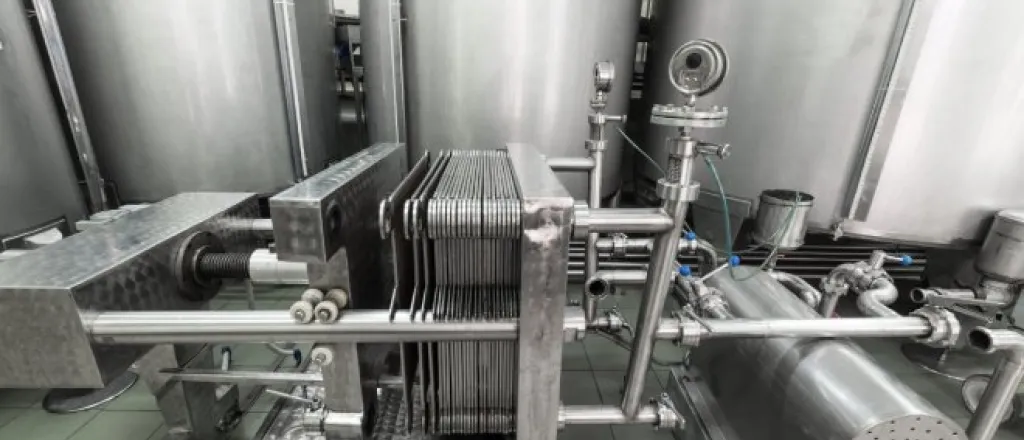

Introduction to Filter Presses

At its core, a filter press is a device used to separate solids and liquids. It’s a workhorse in many industries, helping to remove impurities from liquids and produce dry solids. The process involves pumping a slurry into the press and forcing it through a filter. The result? A cake of solid material and clarified liquid that’s free of contaminants. Now that we have a basic understanding, let’s explore how these machines have evolved.

Early Innovations

Filter presses have been around since the 18th century, initially used for simple operations like juice clarification and dye production. The earliest designs were rudimentary, consisting of a series of wooden plates with fabric stretched over them. Despite their simplicity, these early innovations laid the groundwork for more sophisticated designs.

Industrial Revolution Impact

The Industrial Revolution was a turning point for filter presses. As industries expanded, so did the need for efficient filtration technology. The introduction of steam power and metal fabrication allowed for stronger and more reliable machines. This era saw the development of hydraulic presses, which improved the efficiency and consistency of the filtration process.

Key Evolutions

Over the years, filter presses have undergone significant changes. Advances in materials and engineering have led to the development of automatic filter presses. These modern machines offer numerous benefits, including increased efficiency and reduced labor costs. They come equipped with automatic plate shifters, simplifying the unloading process and allowing for continuous operation. This evolution has made filter presses indispensable in many industries. Automatic filter presses are incredibly beneficial for many industries.

Modern Applications

Various industries use filter presses, from food and beverage to pharmaceuticals and wastewater treatment. In the mining industry, they help separate valuable minerals from ore. In the chemical industry, they purify liquids for further processing. The versatility of filter presses makes them an essential tool for countless applications.

From humble beginnings in the 18th century to modern-day applications, filter presses have evolved and come a long way. Their ability to efficiently separate solids and liquids has made them a staple in many industries. As technology advances, filter presses will undoubtedly continue to play a vital role in industrial processes.